R&D - Production:

At Profelmnet we are investing in new product R&D so that innovation can be utilised to help grow our business as we respond to market requirements. The Company's R&D Department utilises new technologies, methods and techniques to ensure our products improve and are constantly developing, and that all stages of the production process generate the best possible results.

The R&D Department has a very specific philosophy. Working to complex designs that incorporate numerous automation functions, we are able to manufacture easily installable and configurable products. Our aim is to provide dependable products that stand the test of time, which are straightforward and easy for associates to use.

As a company with a vertically-integrated production line, we implement quality assurance procedures covering production conditions and end product quality control in all stages of manufacturing. All company departments implement an ISO 9001 certified quality assurance system and all products bear CE certification.

We ensure the quality of our raw materials, make certain that our machinery is properly managed and maintained and of course check that all our products are in good and proper working order, and also provide customers with a 10-year guarantee.

Production stages

At Profelmnet we take manufacturing of electronic automation systems very personally, and production is completed over 6 different stages under the supervision of experienced staff:

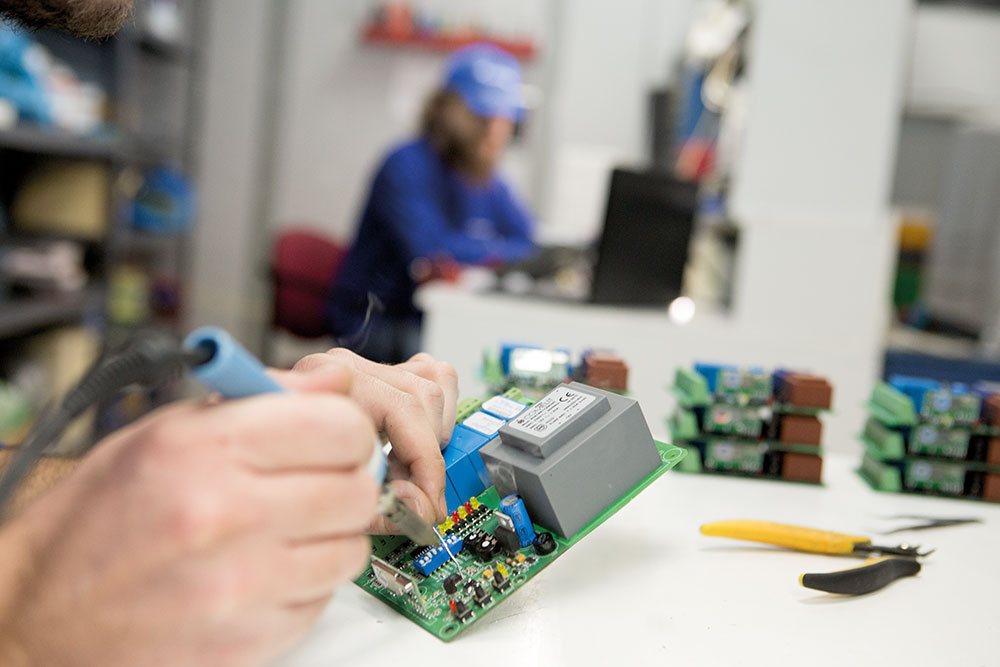

Mounting

All raw materials are placed on a printed circuit board by specialist staff who also perform quality controls on the raw materials for each product individually.

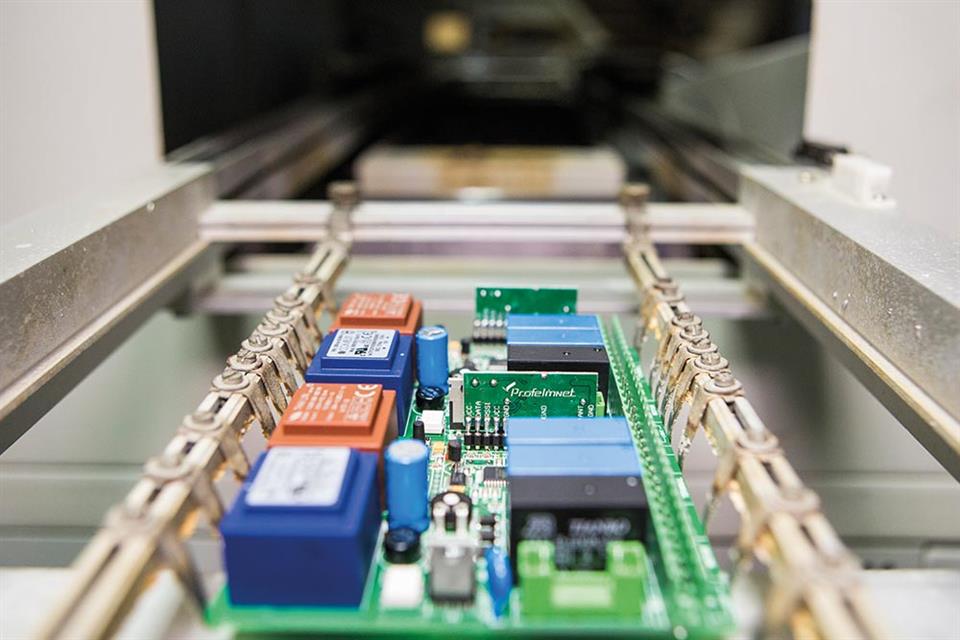

Welding

In this stage all materials used in mounting circuit boards are welded in place with automatic welding devices under the watchful eye of experienced staff.

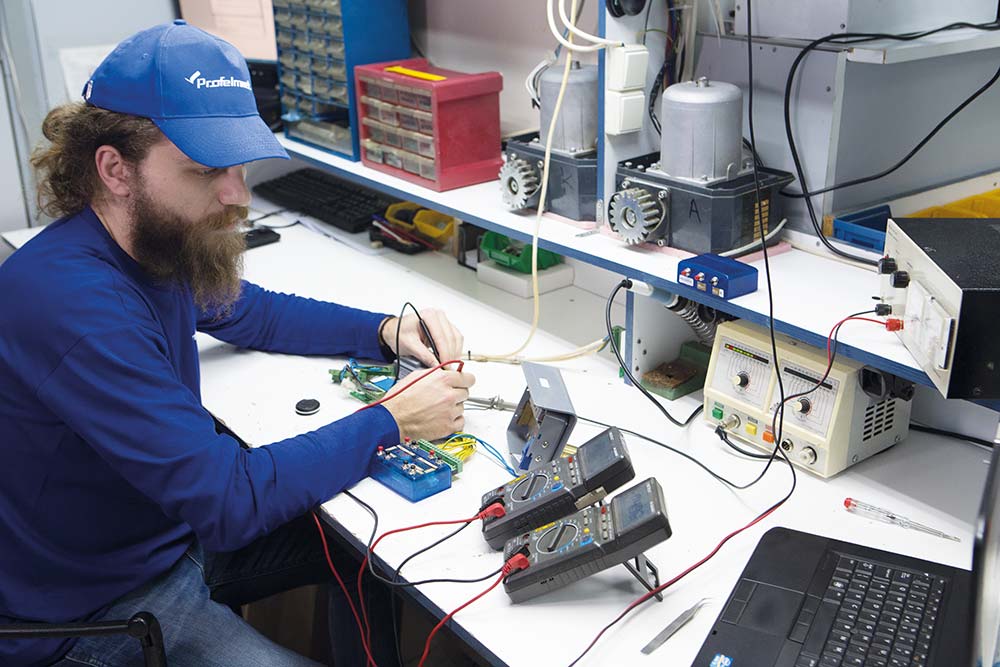

Optical & Quality Control

Then comes one of the most important production stages, with visual and quality controls of each individual circuit board – with each one being checked for how materials were welded and for compatibility (SMD and conventional materials).

Burning firmware

In this stage we programme the circuit boards to meet each individual customer's needs and requirements.

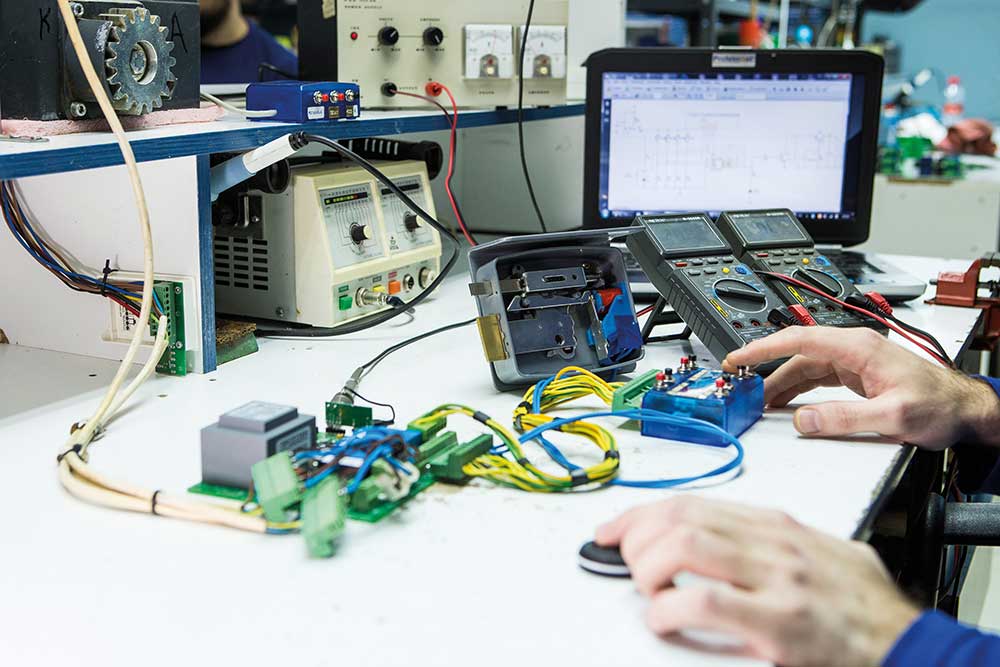

Live operational testing

In this final production stage, we carry out final checks of all possible functions the automated system offers, by simulating operations on the lab bench.

Packaging

All products are placed in packaging accompanied by technical leaflets about installation and assembly.

All our products come with a barcode and description so that associates can easily identify the product. The week it was produced in is also recorded so that we have full control over all lots produced.